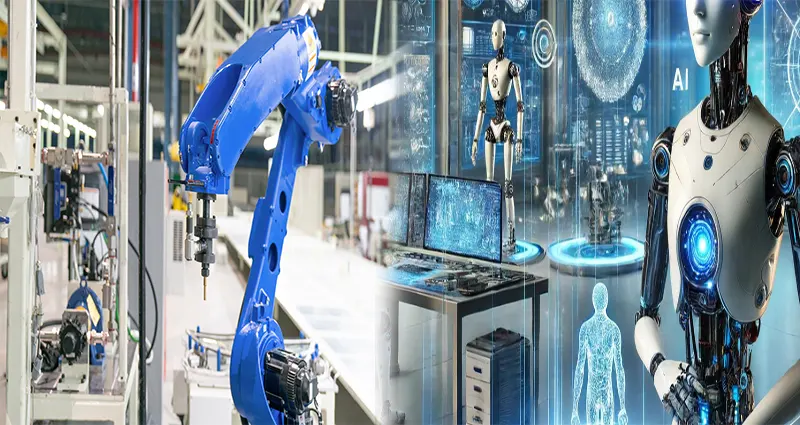

The integration of Artificial Intelligence (AI) into industrial robotics systems has revolutionized the manufacturing landscape, paving the way for greater efficiency, precision, and productivity. By harnessing the power of AI algorithms, industrial robots are now capable of performing complex tasks with a level of accuracy and versatility that was once unimaginable.

The Convergence of AI and Robotics

AI plays a crucial role in enhancing the capabilities of industrial robots by enabling them to adapt to dynamic environments, learn from experience, and make autonomous decisions. This synergy between AI and robotics has unlocked a plethora of benefits for industries, ranging from automotive and electronics to healthcare and logistics.

Key Ways AI Enhances Industrial Robotics Systems

1. Adaptive Learning: AI algorithms empower industrial robots to learn from data and improve their performance over time. By analyzing sensor data and feedback loops, robots can adapt their movements and actions to optimize efficiency and precision.

2. Predictive Maintenance: AI-powered industrial robots can predict maintenance needs based on real-time data analysis, ensuring minimal downtime and maximizing operational uptime.

3. Collaborative Robotics: AI enables industrial robots to work collaboratively with human operators, enhancing safety and efficiency on the factory floor. By understanding the intentions and movements of humans, robots can adjust their actions accordingly.

4. Quality Control: AI algorithms can enhance quality control processes by performing real-time inspections, identifying defects, and ensuring that products meet stringent quality standards.

Benefits of AI-Enhanced Industrial Robotics Systems

The incorporation of AI into industrial robotics systems brings a host of advantages for manufacturers, including:

- Increased Productivity: AI-enhanced robots can perform tasks more quickly and accurately, leading to higher production output and efficiency.

- Precision and Accuracy: AI algorithms enable robots to execute tasks with a level of precision that surpasses human capabilities, ensuring consistent quality.

- Cost Efficiency: By streamlining operations and reducing errors, AI-enhanced robotics systems can help manufacturers save costs in the long run.

- Scalability: With AI, industrial robots can be scaled up or down based on changing production demands, offering flexibility to meet market needs.

Case Studies

Numerous industries have already witnessed the transformative impact of AI-enhanced industrial robotics. A leading electronics manufacturer reported a 30% increase in production efficiency after deploying AI-powered robots for assembly and testing processes, showcasing the tangible benefits of this integration.

The marriage of Artificial Intelligence and industrial robotics has ushered in a new era of automation and efficiency in manufacturing. As AI continues to evolve, industrial robots will become even more versatile, intelligent, and adaptive, reshaping the future of manufacturing and driving innovation across industries.